Indoor shopping mall soft film cloth light box production case

Indoor Shopping Mall Soft Film Cloth Light Box Production Case

Project Overview

This case study outlines the production process of a high-quality soft film cloth light box designed for an indoor shopping mall. The goal was to create an eye-catching, durable, and energy-efficient advertising solution that enhances the mall’s ambiance while effectively promoting brands.

Key Requirements

- Aesthetic Appeal: Sleek, modern design to complement the mall’s interior decor.

- Durability: Long-lasting materials suitable for high-traffic areas.

- Energy Efficiency: Low power consumption with bright, uniform lighting.

- Customizability: Ability to display vibrant graphics and branding.

- Ease of Installation and Maintenance: Simple assembly and quick graphic updates.

Production Process

1. Design and Planning

- Client Consultation: Collaborated with the mall management and advertisers to determine the size, shape, and placement of the light boxes.

- 3D Mockups: Created 3D renderings to visualize the final product and ensure it met the client’s expectations.

- Material Selection: Chose high-quality materials, including:

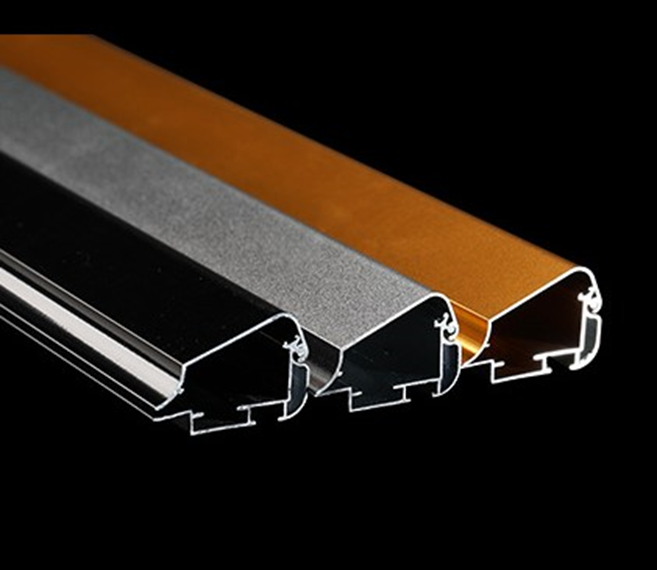

- Aluminum Profiles: Slim, powder-coated aluminum frames for a modern look and durability.

- Soft Film Cloth: High-resolution, UV-resistant fabric for vibrant graphics and even light diffusion.

- LED Modules: Energy-efficient, low-heat LED strips for uniform illumination.

2. Frame Construction

- Aluminum Frame Fabrication:

- Used precision-cut, anodized aluminum profiles (e.g., 10mm thickness) for a lightweight yet sturdy structure.

- Incorporated mitered corners and hidden joints for a seamless appearance.

- Mounting System:

- Designed wall-mounted brackets for easy installation on mall walls or pillars.

- Included leveling feet to ensure the light box was perfectly aligned.

3. Graphic Panel Production

- Soft Film Cloth Printing:

- Printed high-resolution graphics using eco-solvent inks for vibrant colors and fade resistance.

- Applied a UV-resistant laminate to protect the graphics from scratches and wear.

- Edge Binding:

- Used heat-sealed edges to prevent fraying and ensure a clean finish.

- Added grommets or Velcro strips for easy attachment to the frame.

4. Lighting Installation

- LED Strip Integration:

- Installed energy-efficient LED strips (e.g., 120 LEDs/m) along the inner edges of the frame for uniform light distribution.

- Used diffusers to eliminate hotspots and create a smooth, even glow.

- Wiring and Power Supply:

- Concealed wiring within the aluminum frame for a clean, professional look.

- Installed a low-voltage power supply with a built-in dimmer for adjustable brightness.

5. Assembly and Quality Control

- Frame and Graphic Assembly:

- Attached the soft film cloth to the frame using tension rods or magnetic strips for a wrinkle-free finish.

- Secured the back panel to protect the internal components.

- Quality Testing:

- Conducted thorough testing for light uniformity, color accuracy, and structural stability.

- Checked for any defects in the graphics, frame, or lighting.

6. Installation and Maintenance

- On-Site Installation:

- Delivered pre-assembled light boxes to the mall for quick installation.

- Used a team of technicians to mount the light boxes securely and ensure proper alignment.

- Maintenance Plan:

- Provided a user manual for easy graphic replacement and LED maintenance.

- Offered a warranty and regular maintenance services to ensure long-term performance.

Technical Specifications

| Component | Details |

|---|---|

| Frame Material | Powder-coated aluminum (10mm thickness) |

| Graphic Material | UV-resistant soft film cloth with eco-solvent printing |

| Lighting | Energy-efficient LED strips (120 LEDs/m, 12V) with diffusers |

| Power Consumption | 20-30W per square meter |

| Brightness | 2000-3000 nits (adjustable) |

| Dimensions | Customizable (e.g., 1000mm x 500mm, 1500mm x 750mm) |

| Installation | Wall-mounted with hidden brackets |

Results and Benefits

- Enhanced Aesthetics: The sleek design and vibrant graphics added a modern touch to the mall’s interior, attracting more attention from shoppers.

- Energy Savings: The LED lighting reduced energy consumption by up to 50% compared to traditional lighting solutions.

- Durability: The high-quality materials ensured the light boxes remained in excellent condition despite high foot traffic.

- Customizability: Advertisers could easily update the graphics to promote new campaigns, maximizing the light boxes’ versatility.

- Customer Satisfaction: The mall management and advertisers praised the light boxes for their professional appearance and ease of use.

Conclusion

This production case demonstrates how soft film cloth light boxes can be an effective and visually appealing advertising solution for indoor shopping malls. By combining high-quality materials, advanced lighting technology, and a user-friendly design, the light boxes not only met but exceeded the client’s expectations, delivering a perfect blend of functionality and aesthetics.