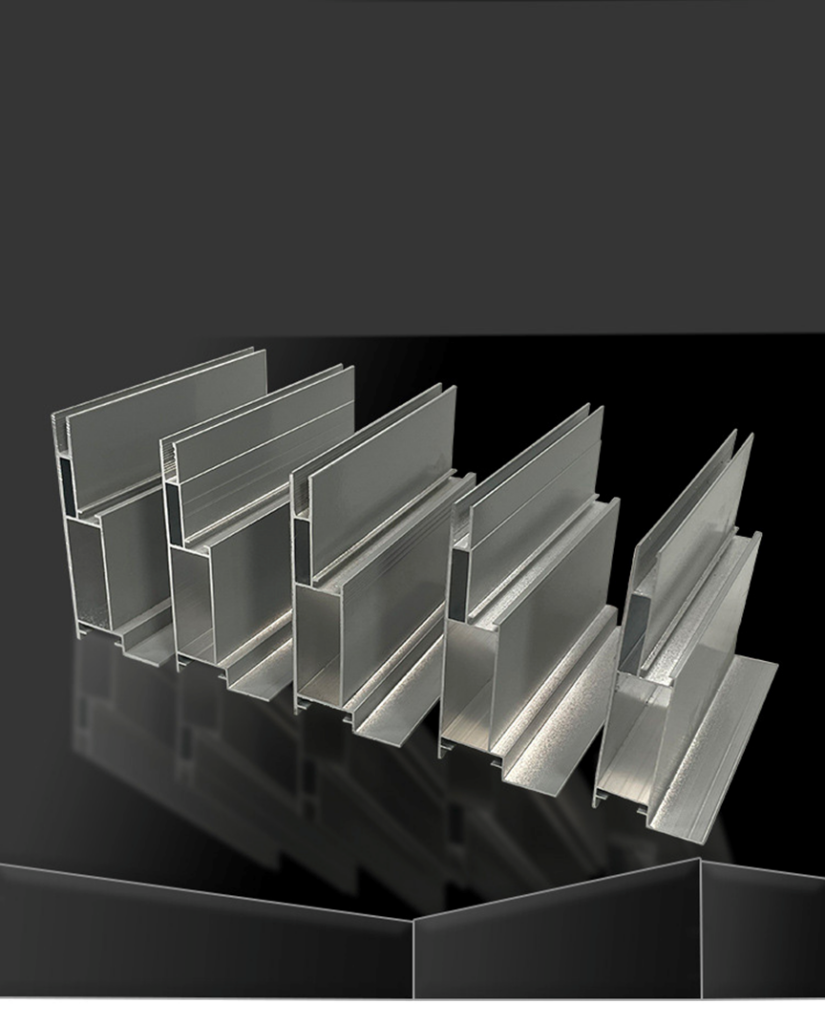

Manufacturers process and customize soft film light box aluminum alloy profiles according to drawings 8 cm single-sided card cloth light box aluminum

aluminium-slot-profiles

Aluminum Light Box Manufacturing

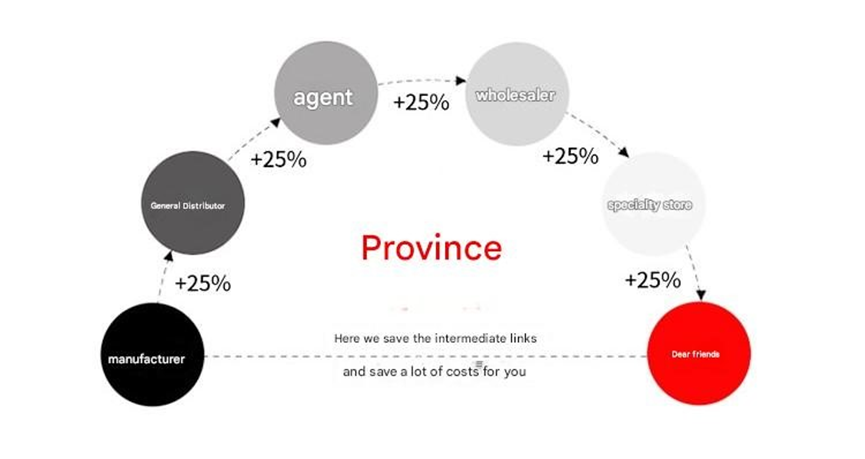

Because we sell directly from the factory

We pass on the profits to you directly

Sketch of the cost chain of factory direct sales products

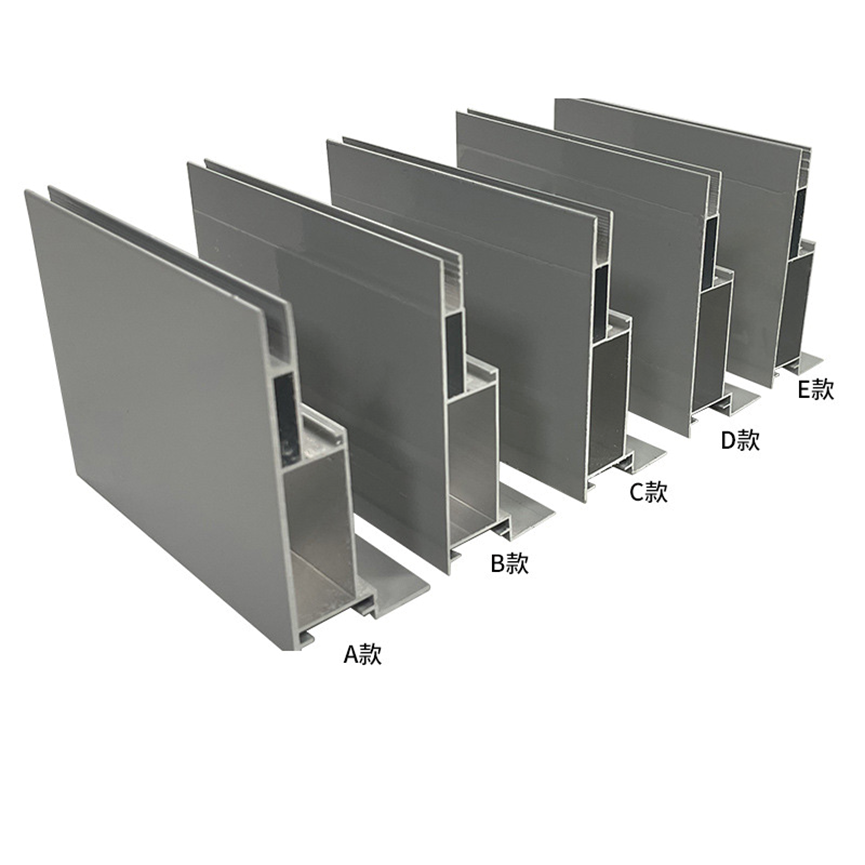

Advertising Light Box Profiles

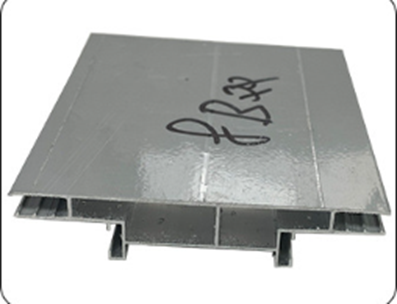

8cm Kabu light box profile

Aluminum wholesale, support processing and customization

Good price Multiple specifications Customizable

Custom Light Box Profiles for Advertising

Careful material selection and rigorous craftsmanship

Customization with drawings and samples is supported

Strict material selection Customization support Considerate after-sales service

Various specifications Timely delivery Manufacturer sales

Aluminum LED Light Box Frames

More Products

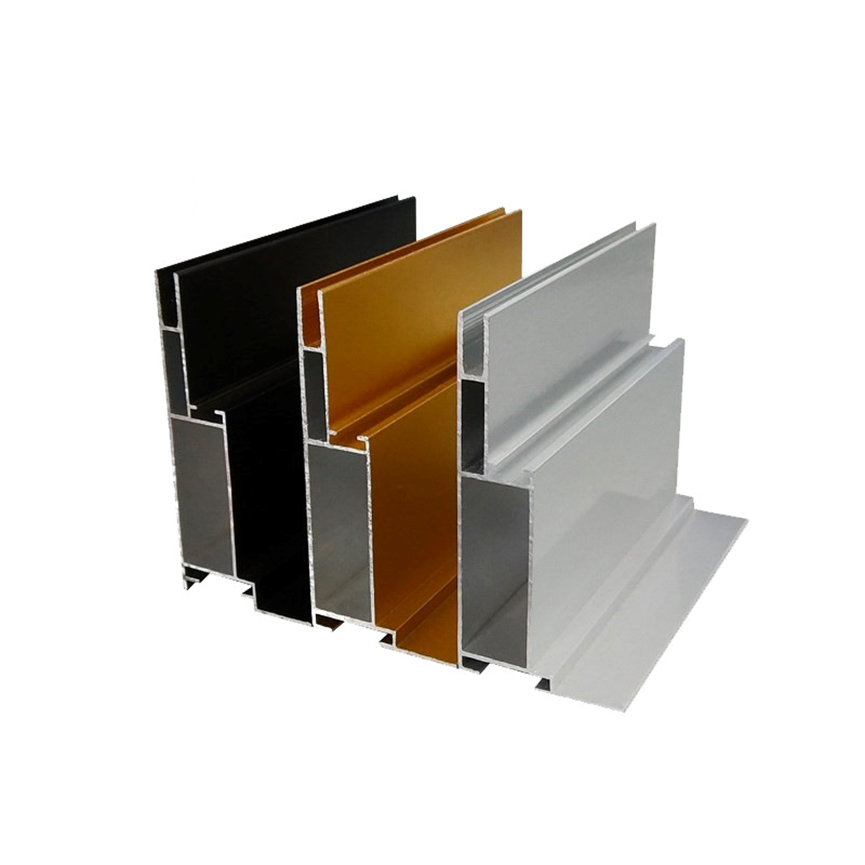

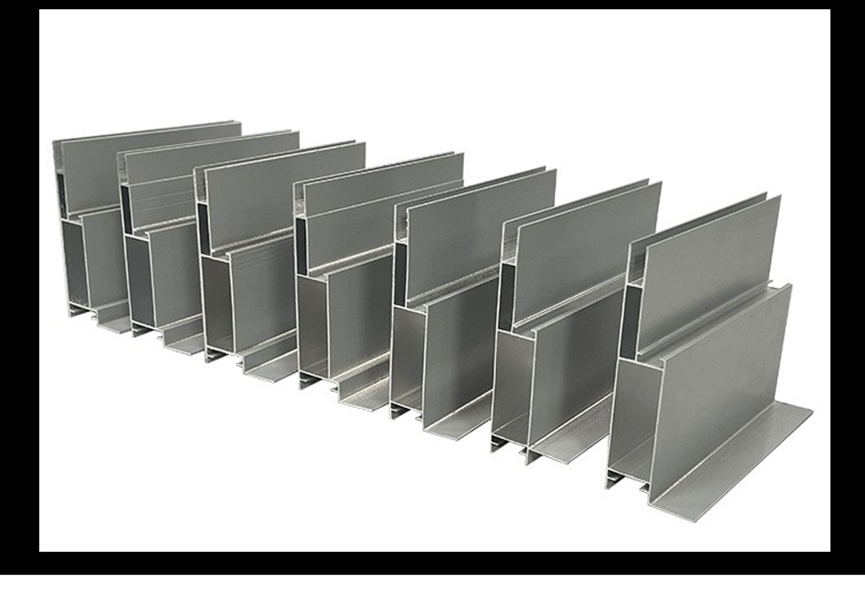

8cm thick single-sided card cloth profile

[Color]: black, electrophoretic color, gold

[Material]: 6063-T5 aluminum

[Size]: 6.05 meters/piece

[Wall thickness]: 2MM

[Card slot]: 4MM wide and 12MM high

8cm single-sided card cloth profile type A

[Color]: black, electrophoretic color, gold

[Material]: 6063-T5 aluminum

[Size]: 6.05 meters/piece

[Wall thickness]: 1.5MM

[Card slot]: 4MM wide and 12MM high

8cm double-sided card cloth profile type A

[Color]: black, electrophoretic color

[Material]: 6063-T5 aluminum

[Size]: 6.05 meters/piece

[Wall thickness]: 1.0MM

[Card slot]: 4.5MM wide and 12MM high

8cm double-sided card cloth profile B

[Color]: black, electrophoretic color

[Material]: 6063-T5 aluminum

[Size]: 6.05 meters/piece

[Wall thickness]: 0.8MM

[Card slot]: 4.5MM wide and 12MM high

Slim Design Aluminum Profiles for Light Boxes

Product Details

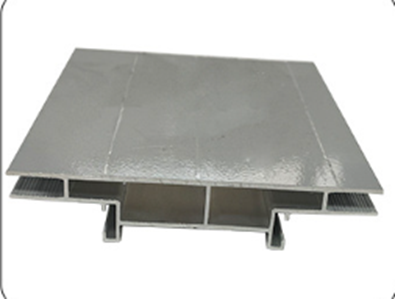

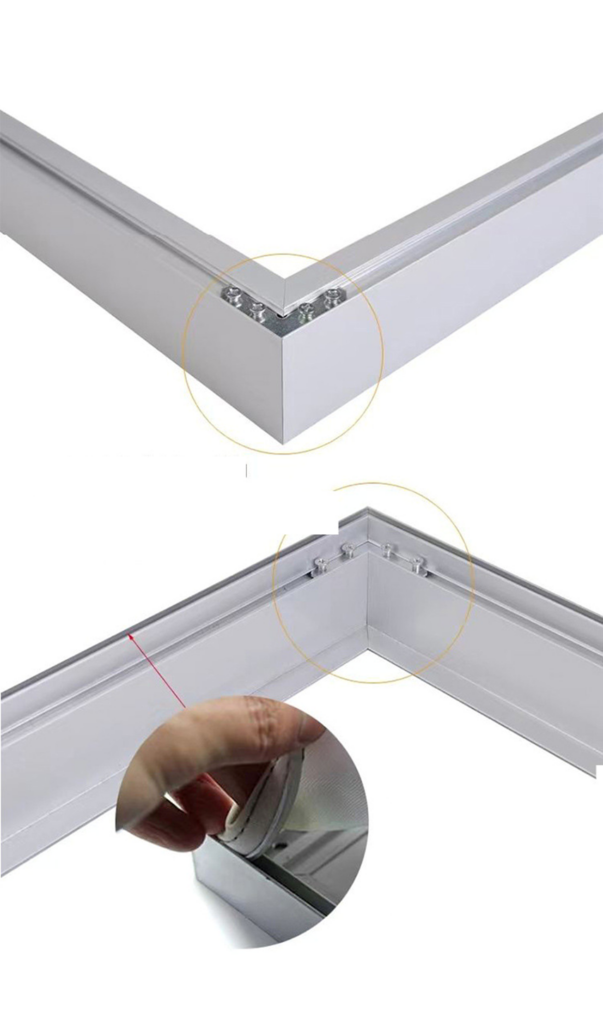

Upgraded safety big corner bracket

The two right angle corner brackets are more stable, and the corner bracket position is exquisitely designed, which is not only easy to assemble, but also quite sturdy.

45-degree seamless splicing

Laser cutting, precise positioning design, smooth and tight seams

Double corners, reinforced design

Upgraded double corners, more even force during light box splicing and installation. Stronger load-bearing capacity

90-degree right angles achieve “seamless splicing”, beautiful and stable

●Double corner code design, aluminum profile right angle

●Using seamless combination professional technology 45 degrees

When splicing, the fit is high

Angle splicing is more stable and not easy to deform

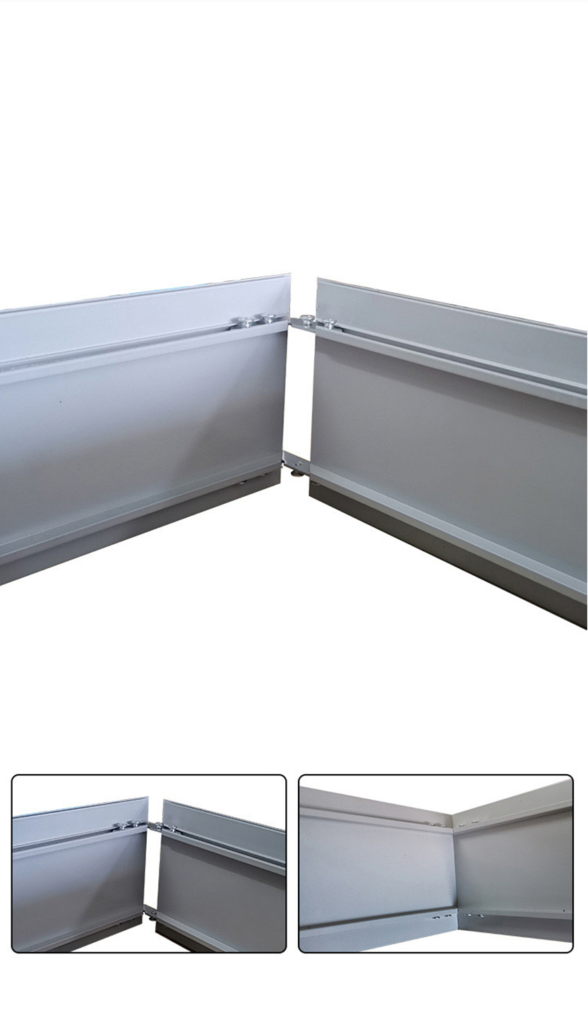

Installation Steps

1. Prepare the profiles and accessories 2.Assemble into a fram 3. Assemble the large and small corners into a 90-degree angle

4. Screw the corners to fix the front 5. Screw the corners to fix the bac 6. Assembly is complete

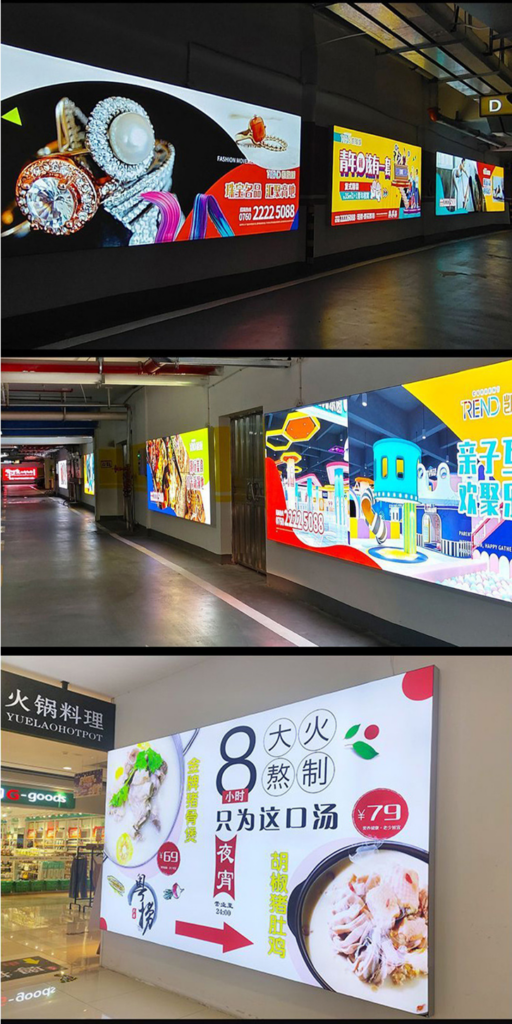

Case scenario display